Managing FSIS Regulatory Framework to Reduce Salmonella Infections Linked to Poultry Products

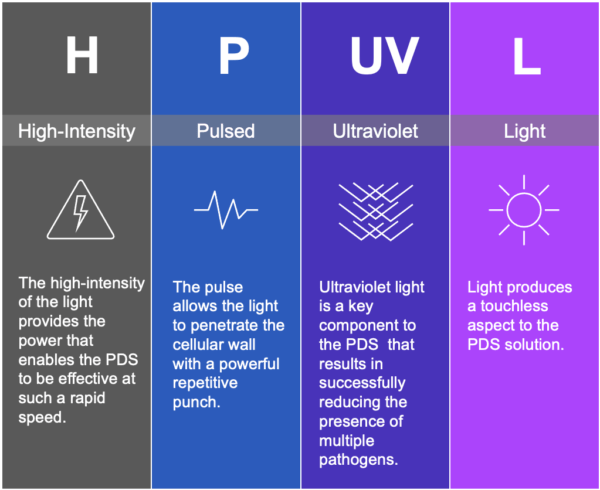

Reducing foodborne infections with High-Intensity Pulsed UV Light (HPUVL) offers many advantages that include the reduction of consumer illnesses. Combining innovation with application, KSI has harnessed the capabilities of HPUVL to offer an environmentally friendly, non-contact, chemical-free, dry method to reduce and in some cases eliminate foodborne pathogens. Our Pathogen Decontamination System (PDS) is now available to be installed and utilized throughout the food and beverage production process.

Reducing foodborne infections with High-Intensity Pulsed UV Light (HPUVL) offers many advantages that include the reduction of consumer illnesses. Combining innovation with application, KSI has harnessed the capabilities of HPUVL to offer an environmentally friendly, non-contact, chemical-free, dry method to reduce and in some cases eliminate foodborne pathogens. Our Pathogen Decontamination System (PDS) is now available to be installed and utilized throughout the food and beverage production process.

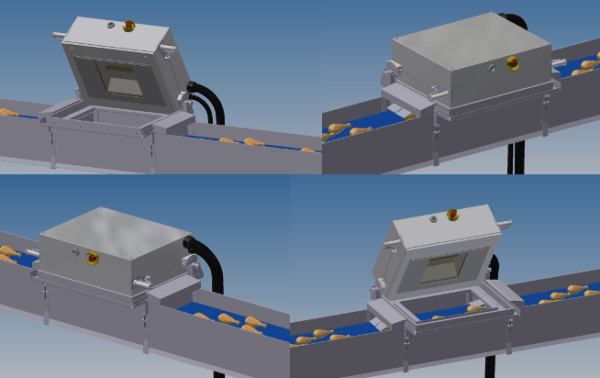

Kreative Systems, Inc. has combined our innovative concepts and global capabilities with PulseForge, Inc., who offer their engineering experience and manufacturing abilities. Together we offer FDA approved food grade in-line, industrial solutions capable of operating at variable rates of speed that can be adjusted to match specific decontamination challenges and settings. Our products and services are offered and supported globally.

The PDS is a light-based, chemical-free, dry, system that can supplement or replace existing decontamination processes to improve results and reduce costs. The PDS provides repeatable, controlled, uniform distribution of power and light with the ability to deliver pulsed energy in a specific rage and pattern. The system features a proprietary Digital Power Delivery System and patented Flash Lamp that delivers both photonic and UV energy to eliminate the pathogens at the wavelengths where they are most susceptible.

Supporting FSIS Quantity Based Testing

The KSI decontamination system can be installed to treat product and equipment at any point along the food processing path. Testing incoming flock before entering an establishment or after slaughter can be coordinated with our patented data monitoring software to ensure product and equipment have received the proper dose of pulsed UV light. In the event that a proper dose has not been achieved to achieve the proper log kill, the system can halt production, quickly correct the fault and then resume production. This process can prevent contaminated product from entering the market and causing illness and possible recalls.

Internal and external tests that have validated the results that the PDS has achieved. The tests have been conducted in our lab, third party nationally recognized, accredited and certified agencies as well as in live production settings. The tests have proven the PDS is capable of meeting, exceeding regulatory guidelines and in some cases eliminating salmonella from raw poultry during the processing stage.

Implementing High-Intensity Pulsed UV Light As A Solution

Our food and beverage supply chain is constantly battling pathogens such as Listeria, Campylobacter (Campy), Salmonella, and E. coli that contaminate food products along the way, from harvest to processing to preparation. The food and beverage industry has proven to be resilient and determined to develop methods for testing and treating throughout the process. The task can be daunting to face on a daily basis. Kreative Systems, Inc. and PulseForge, Inc. have joined in the fight to eliminate pathogens that are harmful to all of us. The “hurdle” concept and mixing of technologies seek to remove, or at least control pathogens in food. The PDS is capable of providing real-time data that can be combined with FSIS regulatory framework to effectively reduce foodborne Salmonella infections.

Improving the Quality and Shelf-Life of Food Itself

Functionality

|

Food Decontamination & Enhancement

|

PulseForge PDS

|

|---|---|

|

In-Line Production

|

|

|

Food Decontamination

|

|

|

Food Conveyor Decontamination

|

|

|

Food Enhancement

|

|

|

Food Package Sterilization

|

|